Innovation to improve performance

RECOGNISED EXPERTISE IN AUTOMATION

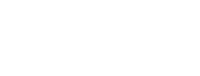

Aktid Smart Solutions have been developed as part of an ambitious R&D plan launched in 2018, based around 3 functional areas:

A PIONEER IN AUTOPILOT SOLUTIONS TO IMPROVE PERFORMANCE

As an equipment manufacturer, Aktid has extensive expertise covering the entire installation process. This is reflected in the Aktid Smart Solutions, which can be integrated with all components of the process as part of a global offer to improve the performance of sorting centres:

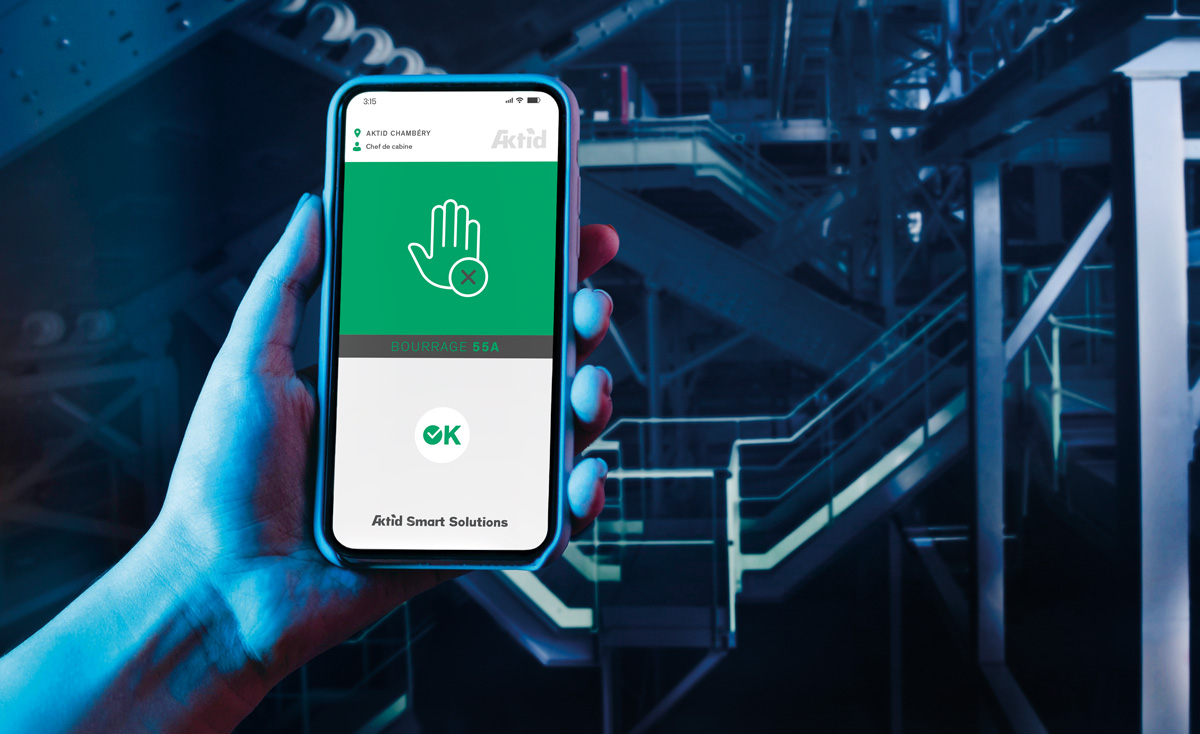

OPERATION ASSISTANCE SOLUTIONS

These innovative tools help staff with day-to-day management, facilitate decision-making and alert them to impending problems.

Manage process performance

Detect the formation of blockages

Warn immediately of any risks detected

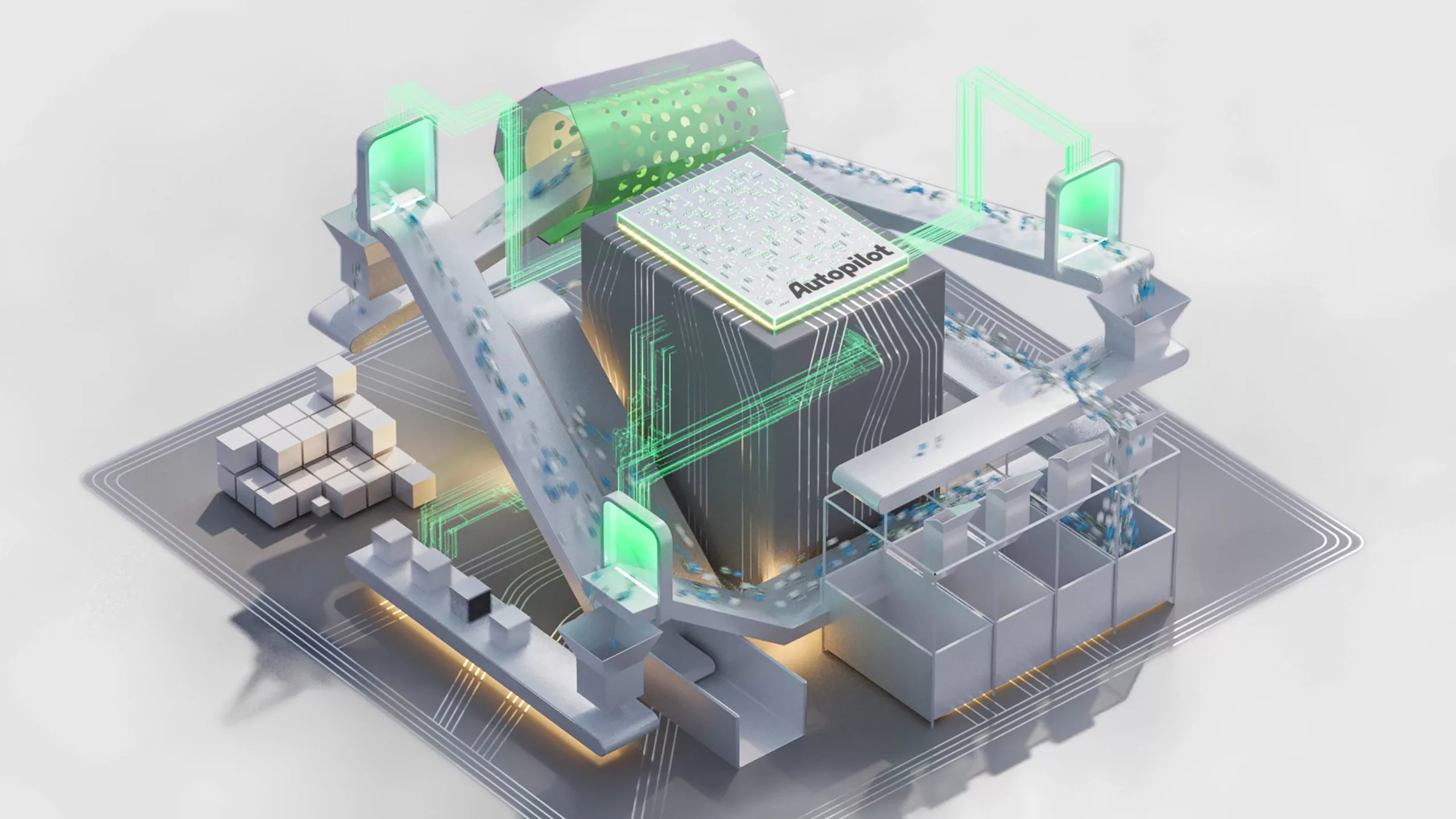

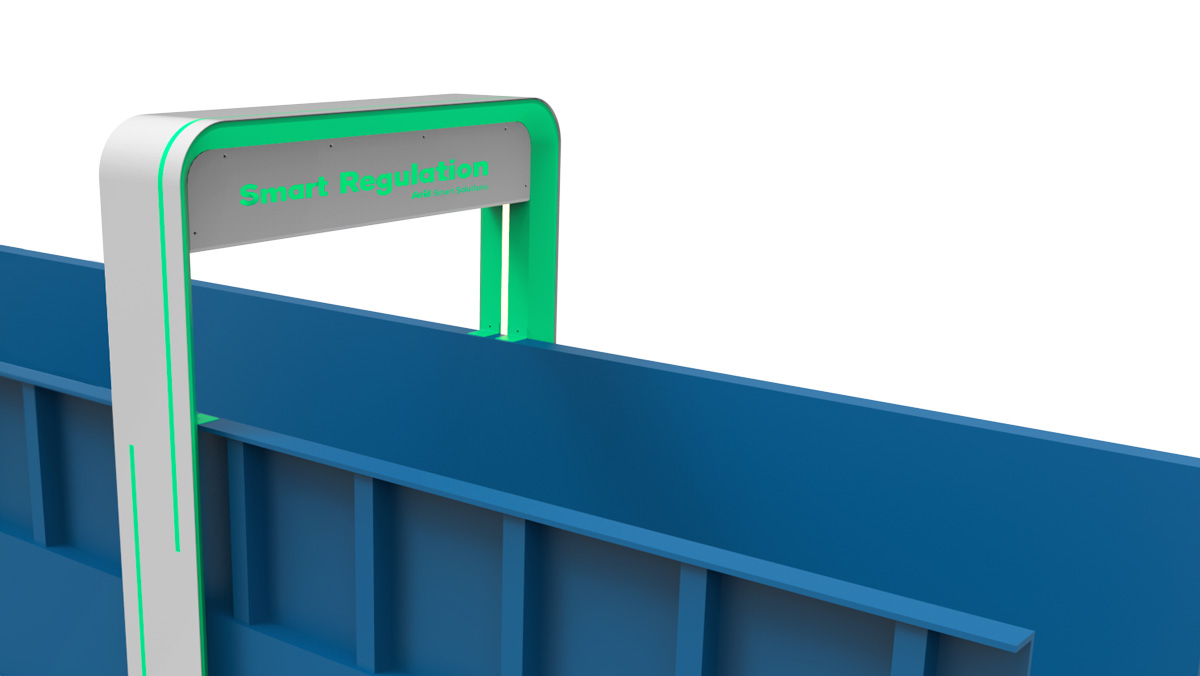

AUTOPILOT SOLUTION

Aktid’s R&D work since the launch of its innovation programme in 2018 is now coming to fruition with Autopilot, the 1st automatic control system for the entire process:

Centralisation and analysis of data collected by:

Automatic detection of variations in:

Real-time adjustment of the settings of each item of equipment to maximise sorting performance.

Stay In Touch