What is

plastic regeneration?

Plastic regeneration is a waste recovery process that reprocesses plastic into a recycled raw material, also known as a secondary raw material. Once reprocessed, the plastic has comparable properties to the raw material.

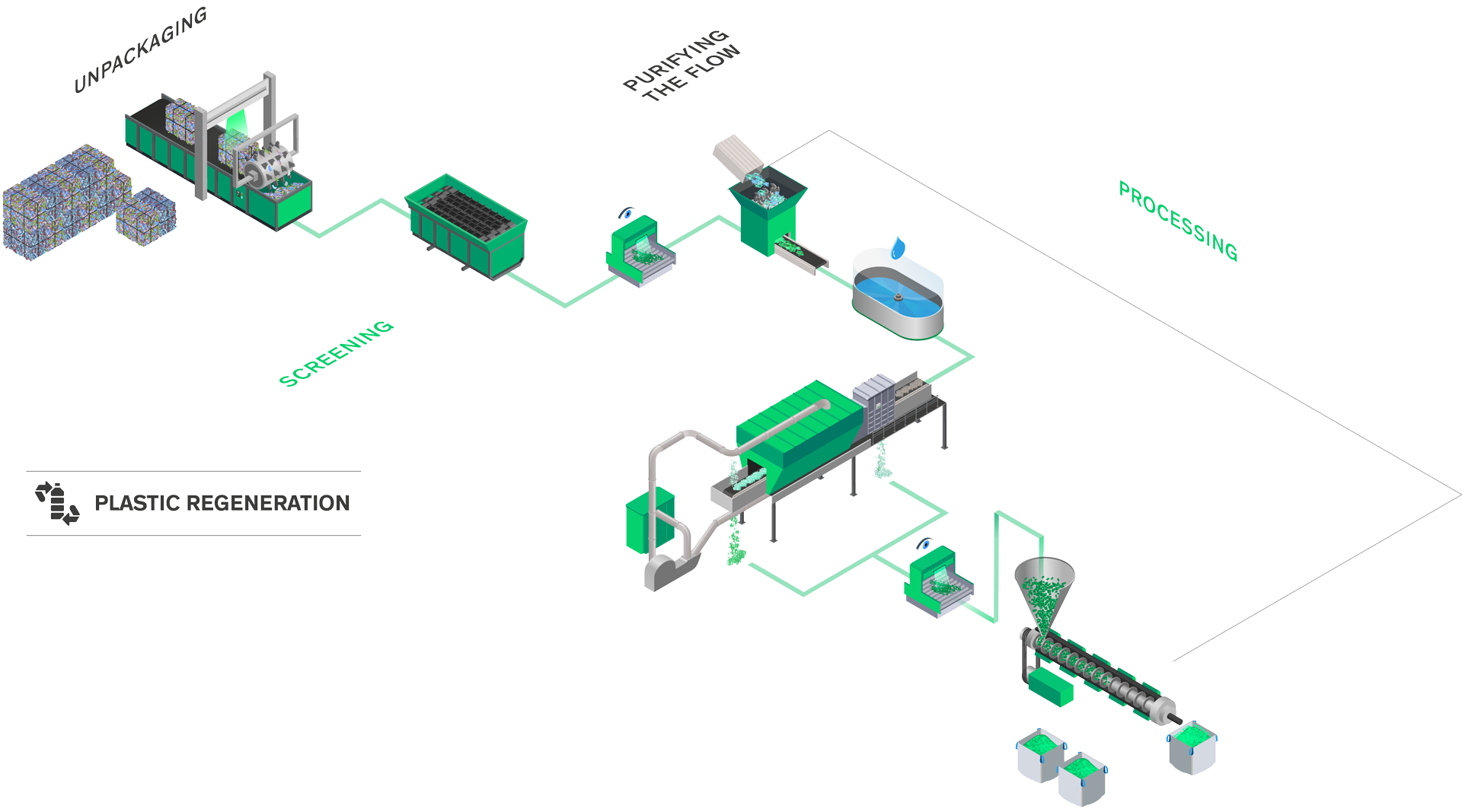

First the plastic is sorted in sorting centres, then it undergoes mechanical secondary sorting on arrival at the recycling centre. This essential step is designed to substantially increase the material purity rate and attain the level necessary for the remainder of the recycling line to operate properly and efficiently as it processes the plastic stream into ready-to-use recycled granules.

The main stages

in regenerating plastic

The plastic bales arriving from the selective collection and sorting centres are decompacted and the bindings removed.

A combination of optical sorters separates out the last remaining intruders to obtain a purity level of over > 99%.

The plastics are crushed and washed to remove any labels, in particular. The bath also serves to separate plastics with different densities. Once dried by an aeraulic separator, the flakes are sorted again by optical sorting machines to eliminate any remaining contaminants. Lastly, an extruder processes the flakes into pellets, ready to be used again as raw material for manufacturing new products.

An AKTID plastic regeneration facility offers :

AKTID facilities

Close-up on: Ballistic separators

Ballistic separators perform the “core process” in next-generation waste-sorting centres. They are used to separate a stream of mixed materials into three or four categories, based on the principle that, depending on their physical properties, materials react differently when they are moving.

The ballistic separator designed by AKTID delivers an excellent quality of separation and processes an additional 30% of throughput by leveraging:

Stay In Touch